Created by Hannah Kannenberg & Johann Bauerfeind at BurgLabs

Created by Hannah Kannenberg

& Johann Bauerfeind at BurgLabs

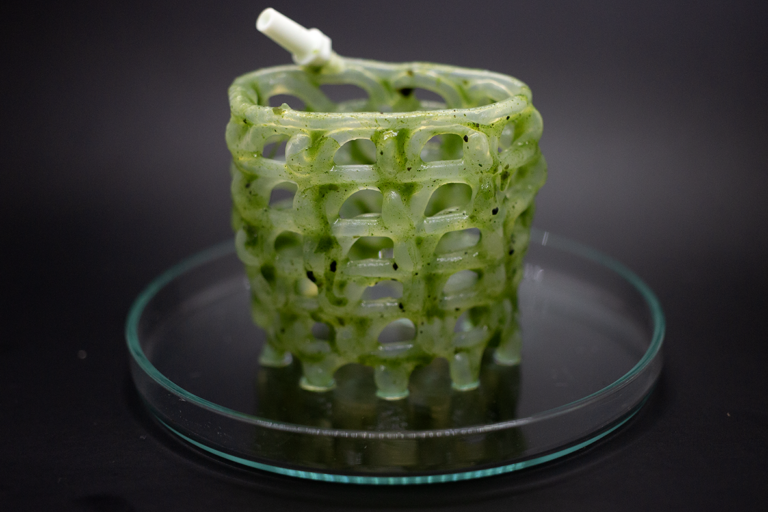

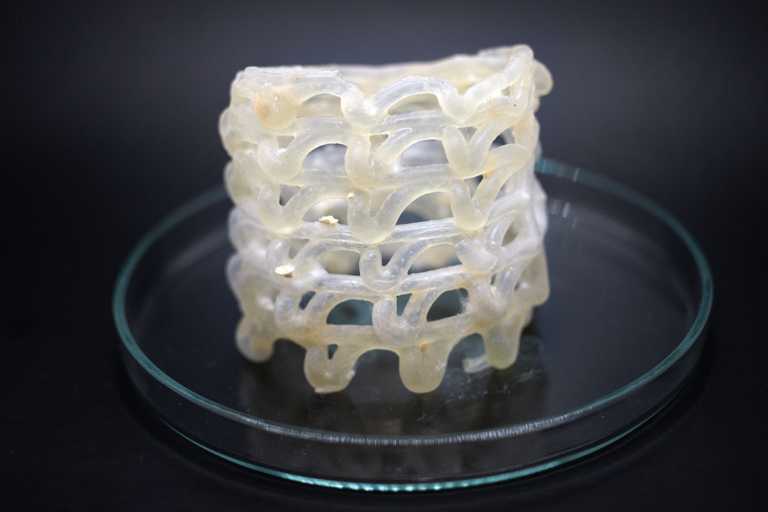

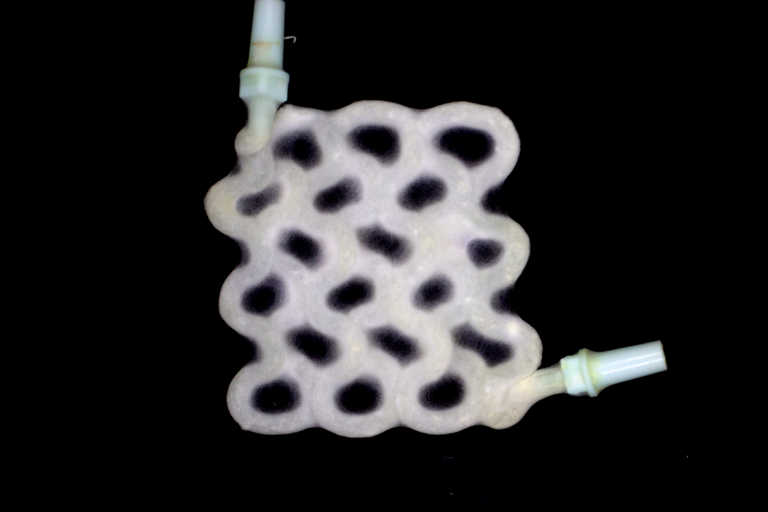

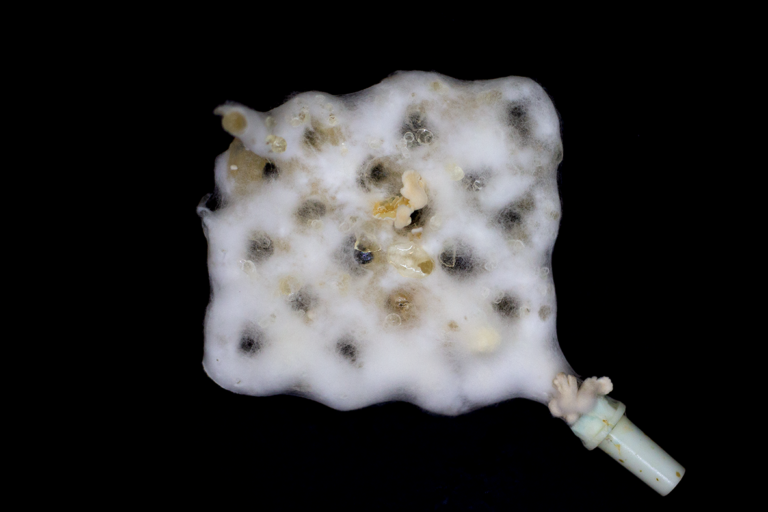

3D hydrogel scaffolds with integrated nutrient supply

The hollow tubes and the semi-permeable hydrogel activally transport nutrients from the inside to the outside. This way organisms or enzymes on or in the material can be supplied with nutrients and other functional elements.

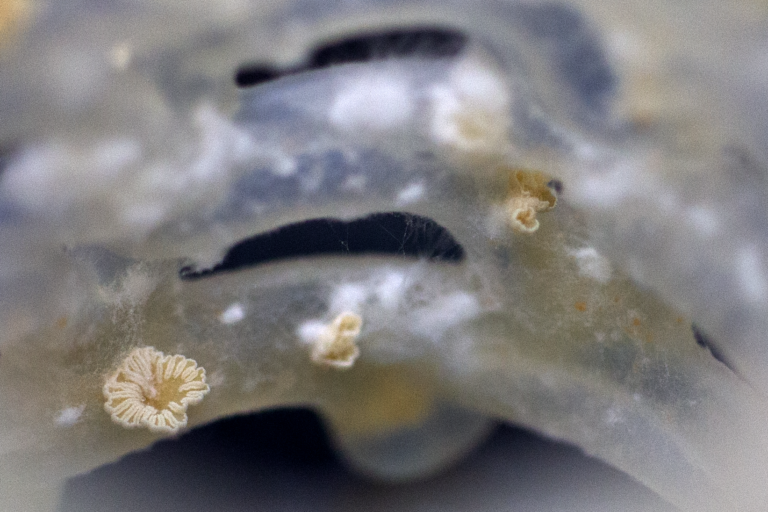

Biotubes are porous

Small molecules such as nutrients diffuse through the Biotubes wall consistently and reproducibly. In the following video, you see Fluorescein a 376 Da molecule diffusing out of the structure in to the surrounding liquid. This allows the supply of nutrients to the surface of the structure.

Complex structures can be designed freely

3D printing biotubes is a highly reproducible process which enables the printing of various complex shapes, formes and structures for various applications and organisms.

Control growth by adjusting media supply

Geometries can be adjusted to use-case and to the individual needs of the organism grown on the biotubes. By supplying media directly through the channels, cell metabolism can be locally controlled and manipulated.

Control growth by adjusting media supply

About the team

Hannah Kannenberg

Johann Bauerfeind

Falko Matthes

Let’s grow together

You are working with your own organims or cell line and would like to experiment with 3D-growth? We are looking for collaborations to test and further develop our versatile structures. Get in touch!

FAQ

You can find more information here in our FAQ section.

Our standard sample structures have a wall thickness of about 0.1-0.3 mm, which are 100-300 µm. In literature, 100 µm is the mean intercapillary distance, which indicates the extent of nutrient diffusion. This value is important in discussions with experts in the field, as it provides insights into designing artificial capillaries that could mimic the nutrient and oxygen diffusion seen in natural tissue. By approximating this scale, our structures aim to support effective cell growth and nutrient distribution in engineered tissues.

Biomaterials such as vegan leather from mycelium, grown textiles or bio-mineralized construction materials are trending. However, often these materials still have to shaped via stitching, gluing, hotpressing or other. Biotubes allow us to shape biomaterials in their growth while controlling growth and thus material properties.

What would happen if instead of “only” the material, we can actually grow a handbag, a shoe, or a piece of furniture directly into final or pre-final stage.

From a design perspective, our main research questions is: What if we could grow products directly into shape.

Rapid Liquid Printing (RLP) is an advanced 3D printing technique where structures are printed directly in a liquid gel or medium. This method allows for the creation of complex shapes and large structures more quickly than traditional 3D printing methods. It’s especially beneficial for creating flexible, customized structures with a variety of materials, including bio-compatible and eco-friendly substances that support the growth and formation of living materials.

You can start by ordering a sample kit, which provides everything you need to begin experimenting with Biotubes. Once you’ve received your kit, our team can assist you in adjusting the hydrogel composition and fine-tuning the printing process to create a structure that’s tailored to your specific requirements. This support ensures optimal growth conditions for the microorganisms or cells you intend to cultivate, helping you achieve the best results for your research or design purposes.

Biotubes have promising future applications in tissue engineering, environmental monitoring, and sustainable manufacturing. In tissue engineering, Biotubes could serve as scaffolds to support cell growth, potentially aiding in the creation of artificial organs or tissues. For environmental applications, they can be designed to filter or detect contaminants in water or air. Additionally, Biotubes show potential as immobilized catalysts, where enzymes or other active agents are embedded within the structure to enable prolonged, stable reactions. This could extend catalyst life, reduce waste, and increase efficiency in various industrial and biochemical processes.

Our Biotubes are designed to be robust in controlled environments, but their durability can vary based on the material and intended application. For certain applications, reinforcement, or coating may be applied to enhance longevity.

Yes, Biotubes are made from natural, biodegradable materials, making them eco-friendly. Depending on the specific use case, they can break down over time in compostable or industrial conditions, contributing to sustainable production cycles.

Absolutely. We offer customization options to tailor Biotubes to specific research or design applications, including size, material composition, and structural features. Please contact us to discuss your requirements.

The sample kit includes 2 – 3 standard structures made of an alginate-based hydrogel structure. The structures are about 5 x 5 cm and have an in and outlet to allow for flow-through of media or chemicals. Additionally, it includes a pump, a culture vessel, various luer-lock connectors and is a pre-made set-up to start cultivating of working with biotubes rapidly.

Visit us

University of Art and Design, Neuwerk 7, 06108 Halle (Saale)

Email Us

info@neobiom.com

Call Us

+49-1525 607 373 4